A bill of materials (BOM) is a list of the components, materials, and quantities required to manufacture a product.

In traditional manufacturing, BOMs are often static, meaning that they do not change once they have been created. However, in today’s increasingly complex and customizable manufacturing environments, static BOMs may not be sufficient to meet the needs of buyers who require customized or configurable products. Let’s find out what is configurable BOM.

What is a configurable BOM (cBOM)?

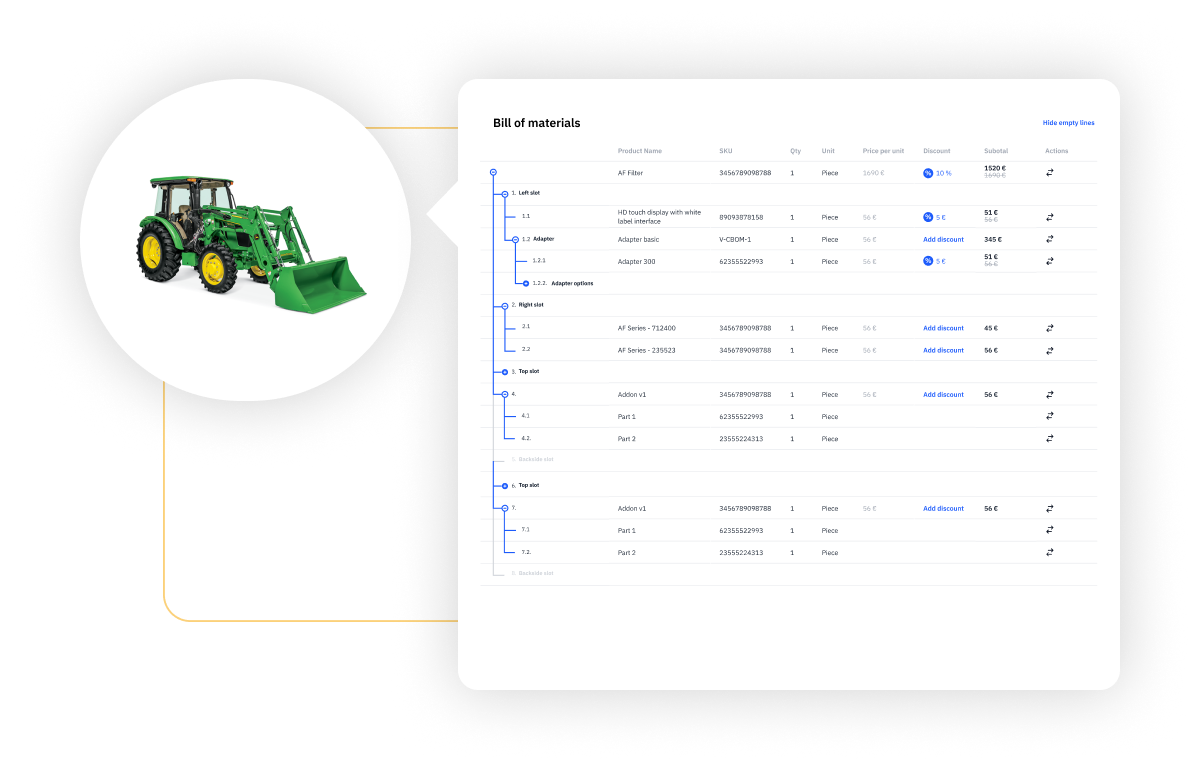

A configurable bill of materials (configurable BOM or cBOM) is a tool that allows manufacturers to create and manage BOMs that can be customized to meet the specific requirements of individual buyers. Configurable BOMs are used in a variety of manufacturing settings, including those that produce customized or configurable products, such as agriculture equipment, industrial components, machinery, medical devices, and automotive parts.

The industry has coined multiple names to cope with the complexity of communication and product development processes in manufacturing organizations. Therefore, the configurable BOM is also known as 150% BOM, customizable BOM, variable BOM, dynamic BOM, modular BOM, adaptive BOM, just to name a few.

Configurable BOMs have optional components or modular subassemblies that define a specific product variation when properly set, streamlining the assembly process. These BOMs contain all possible product BOMs in one structure. When left unconfigured, a configurable BOM includes more parts and subassemblies than needed, leading to the term “150% BOM.”

Benefits of using configurable BOMs

Configurable bills of materials (cBOMs) offer several benefits to manufacturers including improved accuracy, increased efficiency, enhanced customization, better management of changes and updates, improved supply chain management, enhanced collaboration, and streamlined engineering.

Configurable BOMs also enable manufacturers to easily make changes or updates to BOMs as needed and can be linked to other systems such as enterprise resource planning (ERP) or supply chain management (SCM) systems to facilitate supply chain management.

Finally, configurable BOMs can facilitate collaboration between different teams and departments within a manufacturing organization, improving communication and coordination across the organization.

Let’s break down the key benefits of cBOMs:

1. Improved accuracy

Configurable BOMs allow manufacturers to specify the exact components and materials required for a customized product, reducing the risk of errors or omissions.

This can help to ensure that the finished product meets the buyer’s expectations and meets any necessary quality standards. It can also help to avoid production delays or disruptions caused by incorrect or missing components.

2. Increased efficiency

By automating the BOM creation process and integrating it with the sales order, configurable BOMs can help manufacturers reduce lead times and improve production efficiency. This can be especially important when dealing with large numbers of buyers or when production runs are small and customization is required.

Automating the BOM creation process can also help manufacturers reduce the risk of errors or omissions, as the configurable BOM can be set up to enforce rules and dependencies, ensuring that all necessary components and materials are included.

3. Enhanced customization

Configurable BOMs allow manufacturers to offer buyers a wide range of customization options, increasing the value and appeal of their products. This can help manufacturers stand out in a competitive market and build strong relationships with buyers.

Offering customization options can also help manufacturers increase their average order value and margins, as buyers may be willing to pay a premium for customized products.

4. Better management of changes and updates

Configurable BOMs allow manufacturers to easily make changes or updates to BOMs as needed, helping ensure that production stays on track and that buyers receive the products they expect. This can be especially important when dealing with complex or customized products, where changes or updates may be required during the production process.

Having a configurable BOM in place can also help manufacturers respond quickly to changes in market demand or buyer preferences, allowing them to pivot or adapt as needed.

5. Improved supply chain management

Configurable BOMs can be linked to other systems like ERP or SCM to help manage the supply chain. This allows manufacturers to track component and material availability and manage inventory. Effective supply chain management is important for ensuring on-time and on-budget product delivery.

6. Enhanced collaboration

Configurable BOMs can facilitate collaboration between different teams and departments within a manufacturing organization, as they provide a centralized location for storing and sharing information about engineering components and materials. This can help improve communication and coordination across the organization, leading to more efficient and effective operations.

Use cases for configurable BOMs

Configurable BOMs can be used to manage the production of complex products, products with long lead times, mass customization, and complex supply chains.

Configurable BOMs allow manufacturers to specify the exact components and materials required for a customized product, reducing the risk of errors or omissions, and automating the BOM creation process to improve efficiency.

They also allow manufacturers to offer a wide range of customization options to buyers, improving the value and appeal of their products. Finally, configurable BOMs enable manufacturers to easily make changes or updates to BOMs as needed and can be linked to other systems such as ERP or SCM systems to facilitate supply chain management.

Try SaleSqueze CPQ for Free

Experience the power of a modern CPQ for manufacturers with a 30-day free trial access.

How to create a configurable BOM: Step-by-Step Guide

To create a configurable bill of materials (BOM), manufacturers should first define the components and materials that will be used in the product, including any technical specifications or standards that must be met.

They should then set up rules and dependencies for the configurable BOM, defining how different components and materials can be combined or excluded based on the buyer’s choices or requirements.

The configurable BOM should then be linked to a product configurator or other front-end system, as well as to an enterprise resource planning (ERP) system to facilitate product lifecycle, supply chain management, and production planning.

It is important to test and refine the configurable BOM, train relevant teams and departments on how to use it. Furthermore, it is significant to continuously monitor and optimize its performance to ensure that it is meeting the needs of the business and driving efficiency and profitability.

Step 1: Define the components and materials

The first step in creating a configurable BOM is to define the components and materials that will be used in the product, including the final assembly. This includes identifying the types and quantities of each component and material, as well as any technical specifications or standards that must be met. It may also be necessary to source components and materials from external suppliers, which will require coordinating with procurement teams and establishing supplier relationships.

Step 2: Set up rules and dependencies

Next, it is important to set up rules and dependencies for the configurable BOM. This includes defining how different components and materials can be combined or excluded based on the buyer’s choices or requirements, and how each selection might impact the sales order. For example, if a buyer selects a certain option, it may be necessary to include or exclude certain components or materials. Setting up rules and dependencies can help ensure that the configurable BOM is accurate and that all necessary components and materials are included based on the buyer’s selections.

Step 3: Link the BOM to a product configurator

In order to make the configurable BOM available to buyers, it may be necessary to link the BOM to a product configurator or other front-end system. This will allow buyers to select the options and customization choices that they desire, and the configurable BOM will automatically generate the appropriate list of components and materials based on the rules and dependencies that have been set up.

Step 4: Link the BOM to the ERP system

To facilitate supply chain management and production planning, it may be useful to link the configurable BOM to an enterprise resource planning (ERP) system. This will allow manufacturers to track the availability of components and materials, manage inventory levels, and ensure that products can be delivered on time and within budget.

Step 5: Test and refine the configurable BOM

Once the configurable BOM has been set up, it is important to test and refine it to ensure accuracy and that it meets the business’s needs. Testing the configurable BOM may involve running simulations or test orders.

It may be necessary to make updates or changes to the configurable BOM or sales order as needed. These updates may include adding or removing components or materials or adjusting rules and dependencies. Ensuring the accuracy and effectiveness of the configurable BOM is important for the success of the business.

Step 6: Train relevant teams and departments

To ensure that the configurable BOM is used effectively, it is important to train relevant teams and departments on how to use the tool. This may include training sales teams in how to use the product configurator, as well as training production and supply chain teams in how to use the configurable BOM to manage the production process.

Step 7: Monitor and optimize performance

Finally, it is important to continuously monitor and optimize the performance of the configurable BOM. This may involve analyzing data on the components and materials that are being used, identifying any bottlenecks or inefficiencies in the production process, and implementing improvements as needed. By continuously monitoring and optimizing the configurable BOM, manufacturers can ensure that it is meeting the needs of the business and helping drive efficiency and profitability.

Try SaleSqueze CPQ for Free

Experience the power of a modern CPQ for manufacturers with a 30-day free trial access.

Best practices for using configurable BOMs

Maintaining accuracy and up-to-date information is important for effective use of configurable BOMs. Managing changes and updates, and using a centralized system can also help.

Integrating with other systems, monitoring and optimizing performance, training relevant teams and departments, collaborating with suppliers, and using a configurable BOM management system can also be beneficial.

These best practices can help ensure that the configurable BOM is being used consistently and effectively. It helps to reduce the risk of errors or omissions, improve efficiency and collaboration, and drive profitability. Lets learn more about i

1. Maintain accuracy and up-to-date information

It is important to ensure the accuracy and up-to-date nature of the information in the configurable BOM. This involves verifying the availability and specifications of components and materials and making sure the engineering rules and dependencies in the configurable BOM are correct.

Accurate and up-to-date information can help reduce the risk of errors or omissions. This is essential in ensuring that buyers receive the products they expect. Maintaining accurate information is an essential part of effective use of configurable BOMs.

2. Manage changes and updates

Having a system in place for managing changes and updates to the configurable BOM is important. This system may involve using a change management system to track changes and updates. It is also important to communicate these changes to relevant teams and departments.

Having a system for managing changes helps ensure that the configurable BOM remains accurate and up-to-date. This is essential for keeping production on track and avoiding disruptions.

3. Use a centralized system

To facilitate collaboration and coordination across the organization, it is recommended to use a centralized system for storing and managing the configurable BOM. This can help ensure that all teams and departments have access to the same information and can work from the same set of data.

4. Integrate with other systems

It may also be beneficial to integrate the configurable BOM with other systems, such as enterprise resource planning (ERP) or supply chain management (SCM) systems. This can help facilitate supply chain management and production planning, and enable manufacturers to track the availability of components and materials and manage inventory levels more effectively.

5. Monitor and optimize performance

To ensure that the configurable BOM is being used effectively throughout the product lifecycle, it is important to continuously monitor and optimize its performance. This may involve analyzing data on the components and materials that are being used, identifying any bottlenecks or inefficiencies in the production process, and implementing improvements as needed. By continuously monitoring and optimizing the configurable BOM, manufacturers can ensure that it is meeting the needs of the business and helping drive efficiency and profitability.

6. Train relevant teams and departments

Training relevant teams and departments in how to use the configurable BOM effectively is important. This may include training sales teams in how to use the product configurator and how to handle a sales order, as well as training production and supply chain teams in how to use the configurable BOM to manage the production process.

Providing training can help ensure that all teams and departments are using the configurable BOM consistently and effectively. This can help reduce the risk of errors or omissions. Effective use of the configurable BOM requires training for relevant teams and departments.

7. Collaborate with suppliers

To ensure that the configurable BOM is accurate and up-to-date, it may be necessary to collaborate with suppliers to verify the availability and specifications of components and materials. It may also be useful to establish partnerships with key suppliers to ensure that components and materials are available when needed and to negotiate favorable terms.

Collaborating with suppliers can help improve the accuracy and efficiency of the configurable BOM, and can help build strong relationships with key suppliers.

8. Use a configurable BOM management system

Using a configurable BOM management system can help manufacturers effectively manage their configurable BOMs. A configurable BOM management system can provide a centralized platform for creating, storing, and managing configurable BOMs, as well as integrating with other systems such as ERP or SCM systems.

Manufacturers, it’s time to get digital-first with the SaleSqueze CPQ

There’s no time like the present to prepare for the future.

Many manufacturers assume that the products they’re selling are just too complex to be handled by the buyers directly through a self-service online platform, especially when it involves something as intricate as managing a sales order or assembly. The introduction of guided selling and product configuration allows buyers to piece together these complex products and submit them as quotes or orders by themselves.

If you’d like to learn more about the SaleSqueze CPQ, you can book a call with our configuration experts. Our consultants and subject-matter experts are well-versed in what it takes to get you up and running on a visual CPQ Platform.

Try SaleSqueze CPQ for Free

Experience the power of a modern CPQ for manufacturers with a 30-day free trial access.